Insights

5 Real-World Success Stories of Manufacturing Companies that Prepared Their Data Properly to Effectively Implement AI

Data preparation is a critical first step for successful artificial intelligence implementations, as high-quality data is the foundation for accurate and reliable AI models. Manufacturing companies that have prepared their data to implement AI are better positioned to optimize processes and enhance productivity. This blog will showcase five real-world examples of manufacturing companies that excelled in data preparation, unlocking the full potential of AI.

Artificial intelligence is rapidly changing the face of manufacturing, giving benefits that range from efficiency and accuracy to improved productivity in various processes. It is realizing the importance of AI for which manufacturers are embracing the same to stay ahead in today’s competitive global scenario.

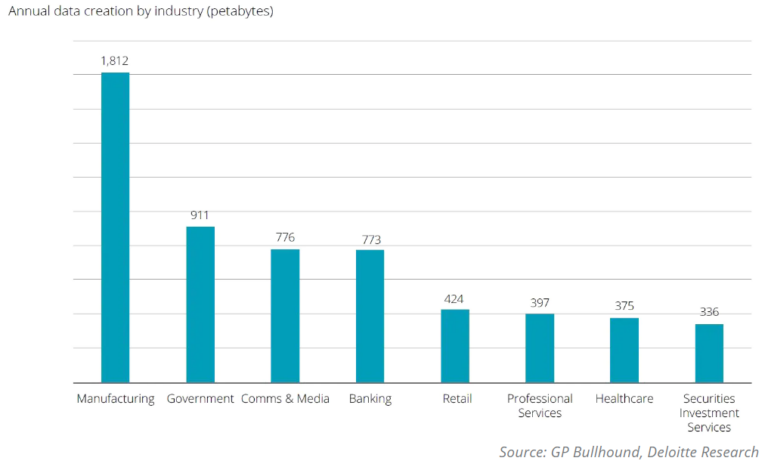

Successful AI implementation is dependent on proper preparation of data. As Deloitte’s study indicates, with massive amounts of data across industries, manufacturing is the leading industry in data production. This data, therefore, is really the fuel for AI, and manufacturers who make data quality a priority and use AI to analyze this meaningful data have a great advantage.

The Impact of AI on Manufacturing

AI plays a crucial role in improving productivity, efficiency, and decision-making processes in manufacturing. Some important applications include:

- Predictive maintenance: AI estimates equipment failure by analyzing its data, hence facilitating maintenance at the right time to prevent potential downtime.

- Inventory management: Machine learning algorithms improve demand forecasting, optimize inventory management, and streamline logistics.

- Quality control: AI-powered QC systems can spot flaws with a greater degree of accuracy, ensuring the quality of the products.

- Assembly line optimization: AI analyzes data to improve accuracy, efficiency, and flexibility in production processes.

How Manufacturing Companies Are Using AI: 5 Real-World Examples

Supply Chain Management: Walmart

Retail giant Walmart utilizes AI to improve efficiency and customer satisfaction in its supply chain. Machine learning algorithms analyze historical data and sales trends to forecast demand and optimize inventory levels. This data-driven approach ensures product availability, minimizes stockouts, and saves money on excess inventory. Additionally, AI-powered routing algorithms optimize logistics for faster and more economical delivery.

Cobots: Amazon

Collaborative robots (cobots) work alongside human operators to increase productivity in fulfillment centers. Amazon’s cobots leverage machine learning to expedite order fulfillment, streamline logistics, and perform complex tasks precisely. Cobots seamlessly collaborate with human workers, minimizing downtime and ensuring optimal equipment performance.

Warehouse Management: BMW

AI is transforming warehouse management. Inventory management is a key area where AI shines. AI algorithms analyze historical data, current stock levels, and market trends to predict demand patterns. This empowers warehouses to optimize inventory levels, reducing carrying costs while ensuring product availability. For instance, BMW utilizes AI-driven automated guided vehicles (AGVs) to streamline intralogistics operations, enhancing inventory management and visibility.

Predictive Maintenance: Rolls-Royce

Rolls-Royce, a renowned manufacturer of jet engines, utilizes AI for predictive maintenance in their engines. They gather vast amounts of sensor data from the engines while they are in operation, including measurements of temperature, pressure, and vibration. This data is fed into AI models that are trained to identify patterns and anomalies that might indicate potential equipment failures. By proactively addressing these issues, Rolls-Royce can prevent costly downtime and ensure the safety and reliability of their engines.

Proper data preparation was essential for Rolls-Royce’s success. They needed to ensure the sensor data was accurate, consistent, and properly labeled. Additionally, they had to develop a robust data management infrastructure to store and process the massive amount of data being collected.

Demand Forecasting: Ford

Ford, a leading automobile manufacturer, uses AI for demand forecasting. They gather data from various sources, including customer surveys, sales figures, and social media trends. This data is used to train AI models that can predict the future demand for specific car models.

Accurate demand forecasting allows Ford to optimize their production processes and inventory levels. They can avoid costly overproduction and ensure they have the right cars in stock to meet customer needs. For successful AI implementation, Ford invested heavily in data cleaning and standardization. They also ensured their data was well-organized and easily accessible for the AI models.

These examples showcase how manufacturers across different sectors are leveraging AI by prioritizing data preparation. By following these approaches, companies can unlock the true potential of AI and gain a significant competitive advantage.

The Importance of Data Preparation for AI Success

The success stories mentioned above all share a common thread: proper data preparation. For AI to deliver on its promises, manufacturers need clean, high-quality data. This includes ensuring data accuracy, consistency, and completeness. By investing in data preparation, manufacturers can unlock the true potential of AI and achieve significant improvements in efficiency, cost savings, and product quality.

Ready to Embrace AI in Manufacturing?

AI offers a powerful path for manufacturers to gain a competitive edge. By following the lead of these successful companies and prioritizing data preparation, you can leverage AI to transform your manufacturing operations and achieve long-term success. Manufacturing companies that prepared their data effectively to implement AI have seen significant improvements in efficiency and innovation.

However, preparing your data for AI can be a complex challenge. Here’s where BrainyYack can help. BrainyYack is a leading digital transformation agency with over 17 years of experience in helping manufacturers leverage cutting-edge technologies. With a global team of engineers, BrainyYack understands the unique data challenges of the manufacturing industry and assists with data cleaning, standardization, and integration, ensuring your data is high-quality and ready to fuel your AI initiatives. From developing a data strategy to implementing best practices, BrainyYack partners with manufacturers to unlock the true potential of AI and achieve significant improvements in efficiency, cost savings, and product quality. Discover more about BrainyYack’s ai innovations here.